Machining stainless steel is a significant area in industrial production, due to the wide application of this material in various industries, from automotive to food and medical industries. Stainless steel is valued for its corrosion resistance, strength, and ability to maintain cleanliness, making it a key material in many advanced engineering applications.

Stainless steel is an iron alloy with added chromium, which gives it characteristic anti-corrosive properties. Chromium forms a passive layer on the surface of the steel, protecting the material from harmful external factors. Stainless steel may also contain other elements such as nickel, molybdenum, or titanium, which further affect its mechanical and chemical properties.

Machining stainless steel is a more complex process than machining most other steels. This complexity arises from several factors:

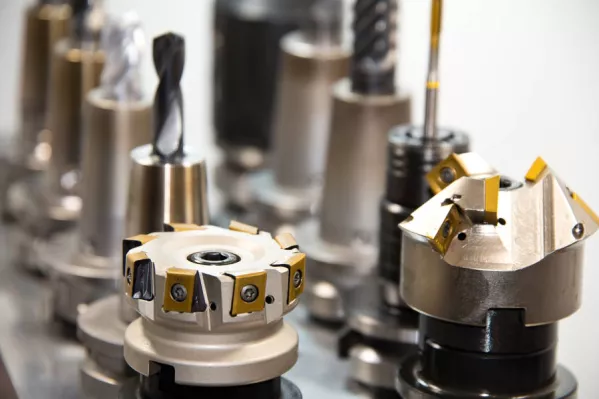

For machining stainless steel, it is recommended to use tools made of cemented carbides or coated with ceramics. These tools are characterized by high hardness and wear resistance, which is crucial when working with hard materials.

Parameters such as cutting speed, cutting depth, and feed must be adjusted to the specifics of stainless steel. Too high values of these parameters can lead to faster tool wear and poorer machining quality.

Using appropriate cooling agents is essential to minimize the impact of heat on the tool and the material being machined. These agents not only cool but also lubricate, helping to reduce friction and tool wear.

Stainless steel is used in many sectors of the industry. In the automotive industry, it is used to produce corrosion-resistant components, in the food industry to create easy-to-clean and hygienic devices, and in medicine to produce surgical tools and implants.

Machining stainless steel requires specialized knowledge and tools, but with modern technologies and techniques, this versatile material can be efficiently and economically processed. Understanding the specifics of stainless steel and using appropriate machining methods are key to achieving high-quality final products.